The industrial landscape is undergoing a massive transformation, with digital twins emerging as a potent force shaping the future of manufacturing. We at Newroom Connect see these intricate virtual models as more than mere replicas; they are a vital component for industry leaders looking to harness the power of data and innovation.

Strategically leveraging digital twins propels operational efficiency and paves the way for new business horizons. In our latest exploration, we examine the multifaceted impact of industrial digital twins and how they are revolutionizing modern manufacturing.

What Are Industrial Digital Twins?

Industrial digital twins have become the keystones of modern manufacturing, serving as comprehensive virtual models that reflect real-world assets, systems, or processes. These dynamic tools encompass a range of components, from detailed 3D models to real-time data analytics, and even simulations that predict outcomes. Unlike static blueprints, these twins evolve, learning and adapting as they ingest new data from sensors and other sources. It’s imperative for industry professionals to understand the composition and utility of digital twins to stay competitive.

The synergy between digital twins and Industry 4.0 is undeniable. As manufacturing pivots towards smarter and more connected systems, digital twins stand out for their ability to synthesize IoT data, machine learning insight, and operational context. This creates a rich digital fabric that not only mirrors the physical world but also predicts and improves upon it. Here lies the true power: digital twins are not just visual replicas; they are decision-making powerhouses driving strategic advancement.

To truly capitalize on digital twins, companies must integrate them deeply into the manufacturing lifecycle. Here are some direct ways to do so:

-

Blend them into the design phase to test and refine products virtually.

-

Implement them in production to monitor efficiency and predict maintenance needs.

-

Utilize twins to optimize supply chains by simulating different scenarios and responses to potential disruptions.

This hands-on approach can lead to significant benefits, with reported cases where companies experienced a reduction in downtime by up to 20% and improved productivity by approximately 25% just by integrating digital twins smartly into their operations.

In essence, the relationship between industrial digital twins and Industry 4.0 is one of intertwined growth and mutual reinforcement. They are not a fleeting trend but a fundamental shift in how we approach manufacturing. Embracing this technology equips businesses to not just ride the wave of digital transformation, but steer it.

To explore more about how digital twins are pushing the boundaries of innovation, check out our deep dive into digital twin development. For practical examples of digital twins in action, our piece on digital twin applications is a must-read.

How Do Digital Twins Transform Manufacturing?

Digital twins have taken the manufacturing industry by storm, primarily by redefining processes and significantly enhancing outcomes. They do so by bringing an unprecedented level of analysis and simulation capability that has radically changed product development and production.

Revolutionizing Product Design

The design phase is the first beneficiary of digital twin technology. Virtual simulation of products allows for a deeper understanding of how a product will perform under a variety of simulated conditions before it ever exists physically. These simulations inform decisions that lead to robust design and reduced time-to-market. For instance, automakers now rely on digital twins to optimize aerodynamics and fuel efficiency in new car models, resulting in designs that might be cost-prohibitive or time-consuming to test physically.

Quality Control at Its Finest

When it comes to maintaining the quality of manufacturing processes, digital twins serve as the ultimate quality-assurance tool. They monitor production in real time, predicting possible defects or wear based on data trends. This predictive capability means that potential issues can be addressed before they become actual issues, leading to high-quality outcomes and savings on costly recalls or reworks. One telling stat is that companies leveraging this predictive quality control have seen a decrease in production errors by as much as 30%.

Optimal Production Through Historical Analysis

Perhaps one of the most potent applications of digital twins is the ability to learn from past production cycles. By analyzing historical data, digital twins optimize every subsequent batch of product. This feedback loop identifies best practices and areas of improvement, creating a more efficient production line over time. It’s a continuous improvement model powered by digital insights, with some manufacturers reporting efficiency boosts of up to 15% after integrating digital twin data into their operational reviews.

Each of these areas represents a leap forward for manufacturers who deploy digital twins strategically. The evolution from static product representation to dynamic, learning, and predictive digital twins marks a turning point in manufacturing—one that smart industry players cannot afford to ignore.

Further insights on how digital twins are changing the manufacturing landscape can be found in our detailed guide on digital twin applications.

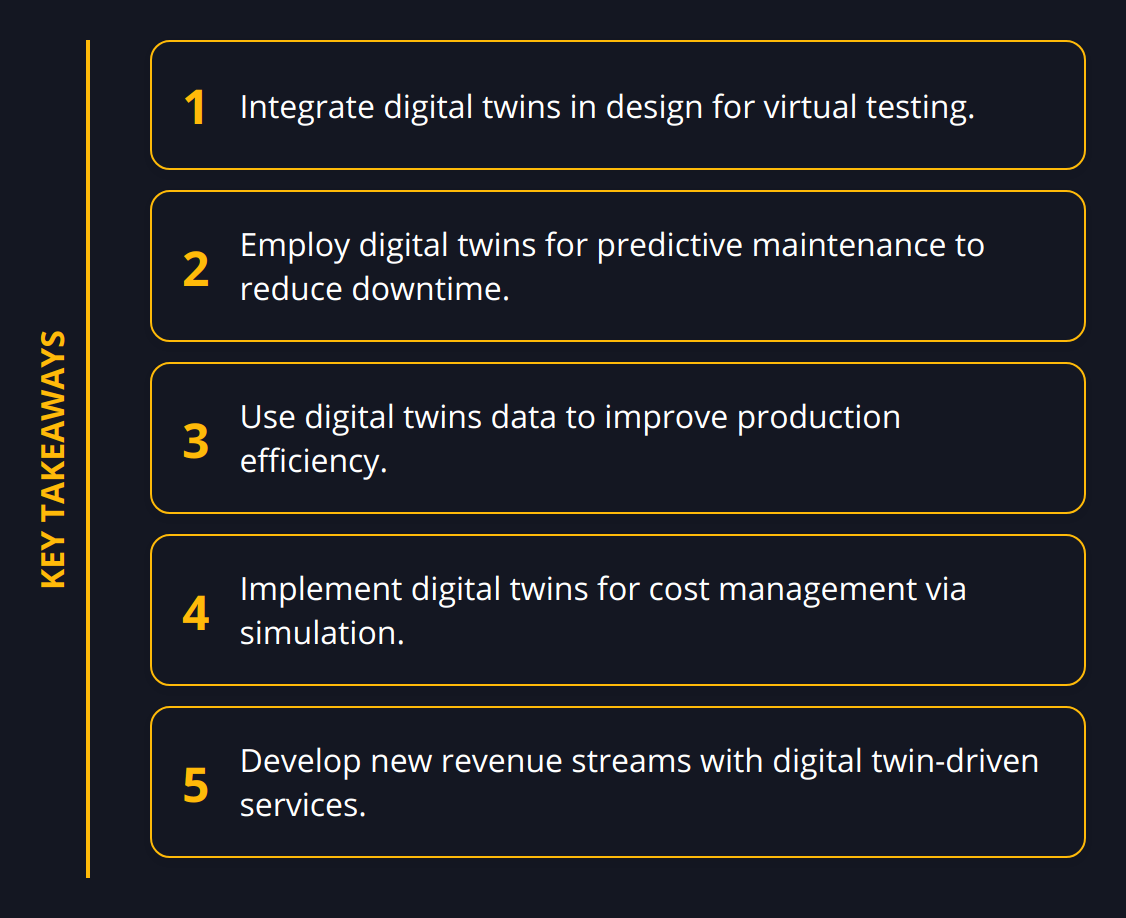

In summary, here are key points for manufacturers to consider:

-

Digital twins can cut design time significantly, enabling faster innovation.

-

Predictive maintenance informed by digital twins can reduce downtime.

-

Comparing new data with historical trends helps in fine-tuning processes.

The journey toward fully integrated digital twins is complex but the benefits for forward-thinking manufacturers are clear and tangible. The smart use of digital twins is not just an upgrade—it’s a fundamental reengineering of manufacturing paradigms.

Harnessing Efficiency Through Digital Twins

In the push to modernize manufacturing, digital twins are more than a technological novelty—they are a strategic imperative for businesses aiming to streamline costs and maximize resource utilization. Imagine the capability to conduct intricate production simulations, tweak processes in a sandbox environment, and forecast outcomes. With digital twins, these are not just imaginings; they’re daily realities driving cost-effective operations.

Refined Cost Management lies at the heart of digital twin technology. By capturing and analyzing real-time data, companies are detecting inefficiencies and reducing waste better than ever before. For example, a digital twin can simulate the energy consumption of a factory, identifying where you can cut costs or adjust usage patterns for peak times. Recent findings suggest companies have lowered operational expenses by an average of 10-12% by employing digital twin technologies for such optimizations.

In Resource Utilization, digital twins shine by ensuring machines and assets are used to their fullest potential with minimum downtime. A digital twin can signal when a machine is deviating from its optimal performance and advise on the necessary maintenance before it leads to costly repairs or replacements.

The avenue of New Revenue Streams and Business Models opened up by digital twins is not mere speculation—it’s today’s reality. Take for instance how manufacturers use digital twins to offer ‘as-a-service’ models, charging for uptime and performance rather than just selling equipment. This pivot to service-based offerings is reshaping revenue models, with recent industry reports indicating a potential increase in service-based income by up to 30% when underpinned by digital twin technologies.

The competitive edge gained through Rapid Prototyping and Customization is palpable. Digital twins facilitate an agile development environment where physical prototyping is minimized, saving time and material costs. This agility allows manufacturers to respond swiftly to customer needs for customized products, bolstering their market position. In the aerospace industry, employing digital twins in prototyping has led to a reduction in development time of new aircraft components by as much as 25%.

To dive deeper into how to leverage digital twins for operational excellence, take a look at our insights on smart factory digital twins.

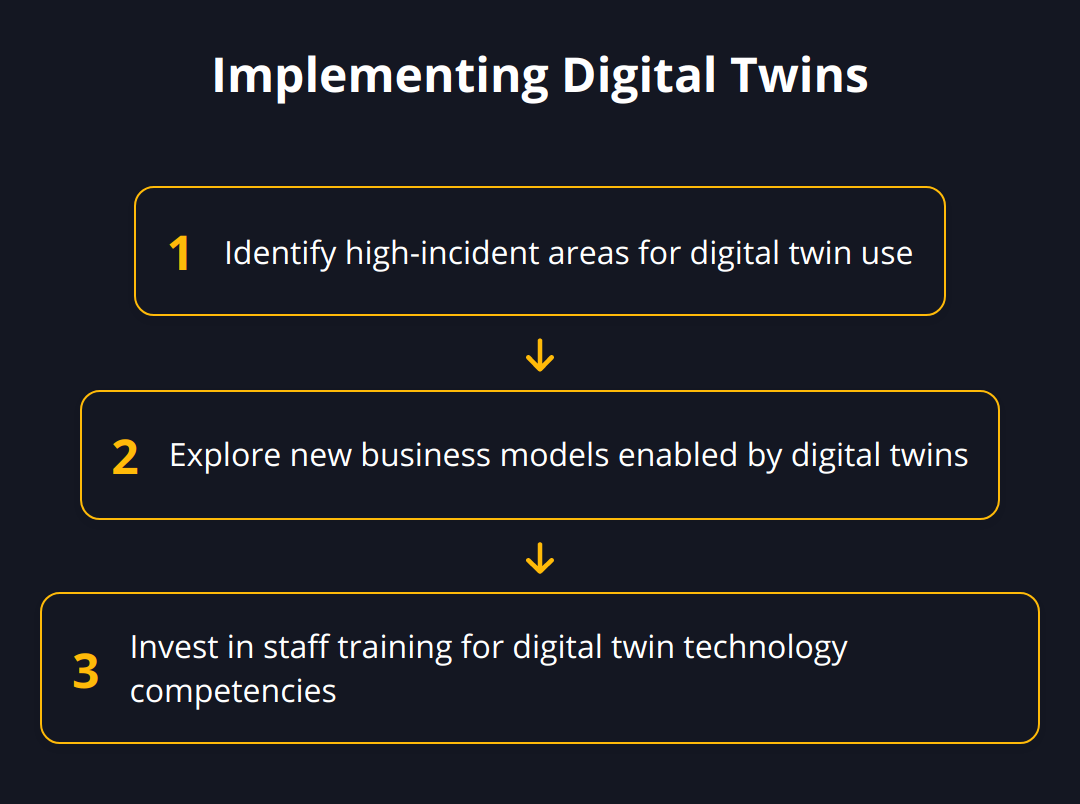

Businesses considering the integration of digital twins must prioritize:

-

Identifying high-incident or high-cost areas for immediate digital twin implementation.

-

Exploring new business models that leverage the predictive and prescriptive power of digital twins.

-

Investing in training to scale staff competencies alongside digital twin technologies.

Digital twins are more than just a reflection of your manufacturing capability—they’re a beacon guiding you toward more intelligent, predictive, and profitable manufacturing solutions. Moving beyond traditional production methods and establishing a strong digital twin strategy today can significantly boost your competitiveness and pave your path to pioneering the manufacturing standards of tomorrow.

Overcoming Digital Twin Hurdles

As the adoption of digital twin technology accelerates across the manufacturing sector, it’s vital to confront and master the challenges that accompany its implementation. The technology’s inherent complexities, the ever-present cyber threats, and the need for seamless integration can seem daunting. However, with a practical and informed approach, these obstacles can be transformed into opportunities for growth and innovation.

Simplifying Complex Systems

Digital twins are inherently intricate, marrying large data volumes with sophisticated models. It’s essential to break down this complexity to facilitate understanding and use. Starting with well-defined objectives and incrementally adding complexity can prevent overwhelm and confusion. Additionally, investing in intuitive platforms and visualization tools can make data more accessible, turning complexity into a competitive advantage.

Maintaining up-to-date and detailed documentation is central to managing these systems. Empower your team to manage, modify, and maintain digital twins with clear guidelines and training. Simplification is not about reducing the digital twin’s capability but making its power more usable.

Fortifying Data Security

With great data comes great responsibility; digital twins often involve sensitive operational data, making them a prime target for cyber threats. A robust security framework is non-negotiable. This includes regular security audits, adopting industry-standard encryption practices, and investing in cybersecurity insurance. Real-time monitoring of systems to detect and respond to threats quickly can limit potential breaches.

Involve cybersecurity experts early in the development process to embed security within the digital twin architecture. If you’re looking for guidance on safeguarding your digital operations, you might find reading about security threats against digital twins helpful.

Streamlining Integration

For digital twins to function effectively, they must be seamlessly integrated into existing systems. This can be formidable, especially with legacy equipment that wasn’t designed to connect to the digital ecosystem. Organizations should focus on developing interfaces and middleware that can bridge the gap between old and new technologies.

Collaboration tools that enable different departments to work together can greatly enhance the adoption process. Success relies on cross-functional teams combining their knowledge to streamline the digital twin into everyday operations. Considering the integration strategy at the initial stages of planning can preempt integration issues later on.

Driving the integration through continuous training and support helps engrain digital twin technology into the company’s culture. When staff see the tangible benefits digital twins bring to their roles—be it through enhanced decision-making, improved efficiency, or predictive analytics—they are more likely to embrace the technology.

In summary:

-

Begin with clear, manageable goals and expand your digital twin’s complexity strategically.

-

Embed security protocols from the onset, and keep abreast of the latest cybersecurity trends.

-

Ensure integration is central to your digital twin strategy, with adequate training to support it.

The exploration of digital twin technology and its implementation should be an iterative, evolving process. Acknowledge the initial challenges as growing pains, and you’ll be well on your way to unlocking the myriad of benefits that digital twins have to offer. For further exploration into the integration of digital twins in your business, consider insights from digital twin marketing strategies.

The roadmap to mastering digital twin technology is carved through practical steps, robust security measures, and all-encompassing integration. The journey may seem complex, but the destination—a more efficient, agile, and innovative manufacturing process—is undoubtedly worth it.

Wrapping Up

As we reflect on the journey through the intricacies of industrial digital twins, their role in the future of manufacturing becomes increasingly apparent. Digital twins are far more than sophisticated digital models; they are the catalysts for innovation, efficiency, and strategic foresight in an industry that is constantly evolving. Their ability to mirror, learn, and predict makes them indispensable for businesses seeking longevity and competitiveness in a data-driven age.

For those in the manufacturing sector, digital twins represent a merge point where virtual and physical realms coalesce to produce optimal performance and illuminate paths to innovation that were once obscure. In a landscape where adaptability and agility are paramount, these virtual models serve as the transformative tools that sharpen a manufacturer’s edge.

We at Newroom Connect recognize the magnitude of what digital twins offer, and we encourage manufacturers to make the bold leap into their adoption and integration. The investment in digital twin technology goes beyond immediate returns; it’s about securing a foothold in a rapidly advancing technological frontier. Forward-thinking companies will find in digital twins a foundation for growth, sustainability, and new avenues for customer engagement.

Embrace the Digital Shift with a focus on:

-

Strategic implementation: Identify where digital twins can make an immediate impact.

-

Operational foresight: Use the predictive power of digital twins for maintenance and quality assurance.

-

Cost efficiency: Optimize resource utilization and explore new revenue models.

-

Innovation impetus: Employ digital twins for rapid prototyping and market responsiveness.

We stand on the brink of a new era in industrial manufacturing, one that is set to redefine not just how we operate but also how we conceptualize the relationship between data and physicality. At Newroom Connect, we offer virtual solutions tailored to meet the evolving needs of companies navigating this seismic shift. Through virtual trade fairs, showrooms, and e-learning platforms, we aim to accelerate your journey towards digital mastery.

Digital twins are, without doubt, the backbone of modern manufacturing. Their adoption is not just advantageous—it’s essential. They equip manufacturers with vital knowledge and control, driving a future where the boundaries of what’s possible are constantly expanding. The call to action is clear: invest in digital twins and secure your place in the vanguard of industry leaders.

In closing, the transformative potential of digital twins is undeniable. By integrating these advanced technologies, businesses can attain previously unreachable levels of precision, innovation, and efficiency. As partners in your digital voyage, Newroom Connect is here to facilitate that integration, helping your enterprise not just to adapt but to lead in the new digital paradigm of modern manufacturing.