Understanding the intricate fabric of digital twin technology offers a glimpse into the future of industry and urban development. This advanced concept is shaping up to be a game-changer in how we design, manage, and optimize various systems and environments.

We at Newroom Connect are excited to shed light on the framework and utilization of digital twins, offering you a guide through its complex development process to practical applications. Let’s explore how this innovation is transforming operations and what it takes to navigate the associated challenges effectively.

Why Digital Twins Matter

The digital twin is more than a buzzword; it represents a monumental shift in how organizations operate and innovate. Essentially, digital twins are comprehensive virtual models designed to accurately reflect physical objects. Their significance across industries is underlined by the transformative capabilities they bring to the table – from advanced analytics to predictive maintenance and strategic planning. They are not merely a replica but serve as a dynamic tool for understanding and manipulating the real-world counterpart in a risk-free digital environment.

Over the years, the importance of digital twins has surged, with a robust market growth prediction—reaching up to $73.5 billion by 2027, underpinning their expanding role in large-scale projects and sectors like manufacturing and urban development. The adoption rate is persuasive as well, with reports showing a solid increase in job posts related to this technology, averaging an 11% uptick compared to the previous year.

Delving into the developmental history, the journey began in 1991 and gained traction in the manufacturing realm by 2002. Fast forward, we now stand at the cusp of a digital twin evolution, with a progressive compound annual growth rate (CAGR) of 30% anticipated between 2023 and 2027. This sharp trajectory signals a clear verdict – digital twins are central to future innovation and efficiency, not just passing technological fads.

Building a digital twin involves compiling a meticulous architecture, comprising hardware like IoT sensors and actuators, sophisticated data management middleware, and an array of software elements like analytics engines. This holistic system creates a cohesive digital thread that binds the physical and the digital, making iterative operations from data collection to analysis an integral part of everyday business processes.

Furthermore, practical applications tell the real story of their value. For instance, the aerospace industry employs digital twins for timely engine maintenance, while automotive giants like Tesla rely on them for remote vehicle diagnostics. In the energy sector, they predict the performance of turbines, and supply chain simulations leverage them for enhanced logistical transparency.

Therefore, organizations interested in the advantages of digital twins should embrace certain key practices. Firstly, choose a fitting twin type that matches the complexity of the subject, be it a component or a systematic operation. Secondly, investments in both tangible and intangible assets, including hardware and skillsets, cannot be compromised. Finally, review ready-made solutions from industry leaders carefully to shorten the runway to digital twin deployment.

In conclusion, the value of digital twins is immense, and while their implementation is not devoid of challenges, their integration into your operations can lead to significant rewards. As we continue to push the bounds of digital innovation, expect these virtual counterparts to become an indispensable part of your toolkit. For a deeper understanding of leveraging digital twins for innovation, explore our insights on harnessing the power of digital twins.

Key points to ponder for organizations looking at digital twins:

-

Market Growth: By 2027, digital twins are set to form a massive market worth $73.5 billion.

-

Job Market Influence: An 11% increase in digital twin-related job postings.

-

Practical Benefits: Industries like aerospace and automotive are heralding new efficiencies by employing digital twins.

-

Architectural Considerations: A blend of hardware, data management, and software is key to building a functional digital twin.

-

Implementation Strategy: Choosy adoption, strategic investment, and partnering with industry leaders can streamline the digital twin integration.

Crafting a Digital Twin

Embarking on the journey of creating a digital twin, we emphasize a structured and methodical approach. This ensures not only a robust end-product but also a scalable and adaptable solution that can evolve alongside the physical asset it mirrors. Here’s how to navigate each development phase effectively.

Initial Planning and Blueprint Creation

Developing a digital twin starts with a clear vision and an actionable blueprint. This phase is about defining the scope and purpose of your digital twin. Ask yourself, what’s the intended use? Is it for product development, operations, or maintenance? Your goal here is to establish a detailed and targeted outline that will direct all subsequent efforts.

Remember, a common error is biting off more than you can chew. Therefore, start with a focused application, such as a component twin if you’re tackling a complex system, or a process twin for holistic operation monitoring. Use strong data governance from the get-go, ensuring that data quality and security are prioritized.

Building the Base Digital Twin

With a blueprint in hand, it’s time to construct the foundational layers of your digital twin. This includes integrating IoT devices, setting up network communication, and implementing the initial data models. Your aim is to create a responsive system that can communicate with its physical counterpart in near real-time.

In this build phase, stick to the principle that your digital twin must be both accurate and efficient. It’s tempting to model every detail, but excessive granularity can lead to data overload and increased computational demand. Instead, focus on the most critical aspects to achieve optimal performance without draining resources.

Iterative Development and Capability Enhancement

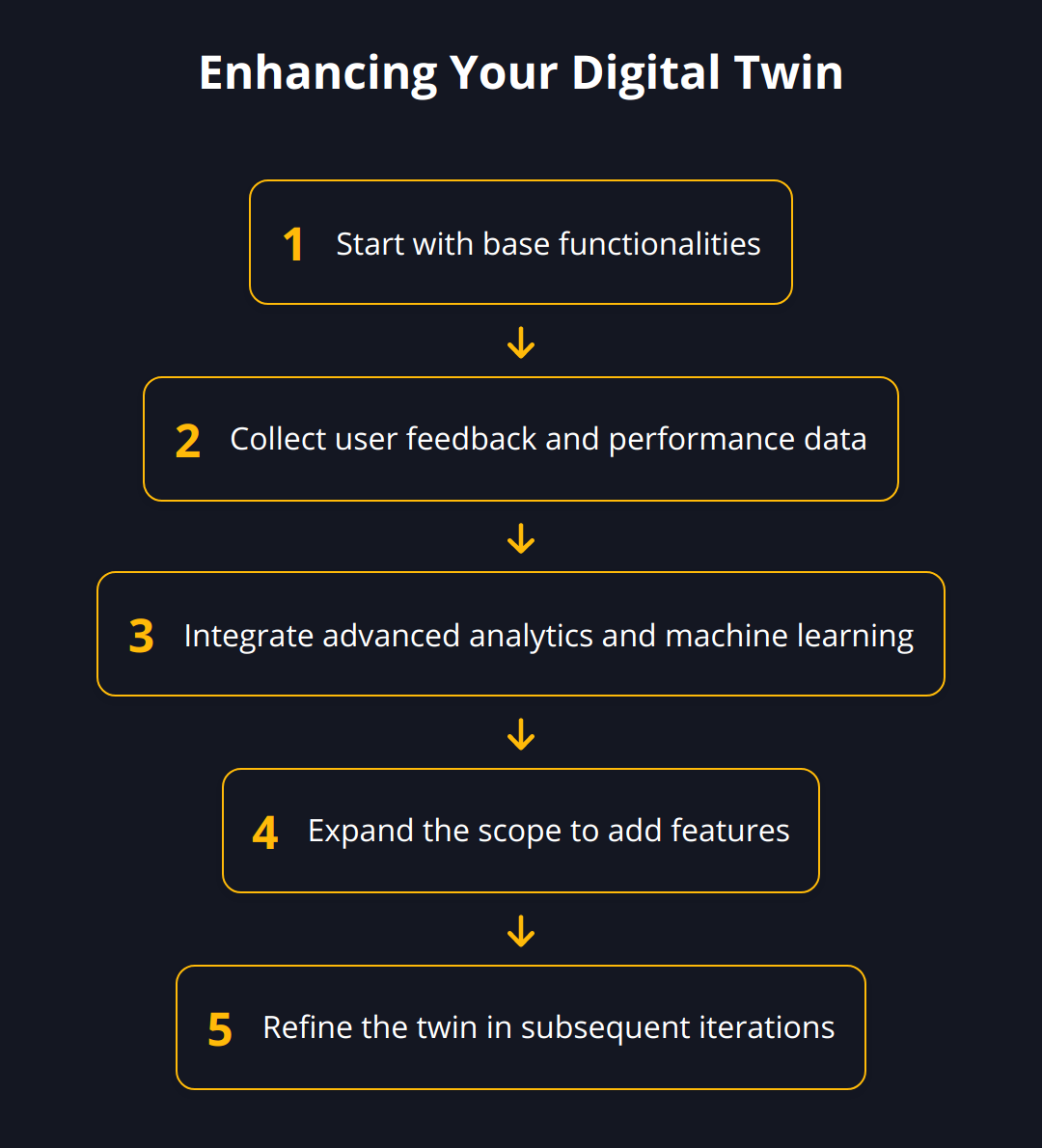

Once the base of your digital twin is operational, the process evolves into one of iterative improvement. Enhance capabilities by integrating more advanced analytics, machine learning algorithms, or by expanding the scope of the twin to include additional features or systems.

Progressive enhancement is key—each iteration should aim to refine the digital twin based on user feedback, performance data, and evolving business needs. It’s also vital to keep an eye on interoperability; as your digital twin matures, ensuring it can communicate with other systems and data sources becomes increasingly important.

Throughout these phases, we’ve seen companies flourish by adhering to these guidelines:

-

Define the purpose: A twin created for maintenance differs greatly from one designed for product development.

-

Prioritize data integrity: High-quality data is the lifeblood of any digital twin.

-

Seek scalability: Choose technologies and platforms that allow your digital twin to grow alongside your ambitions.

By following this approach, you can expect not just to build a functional digital twin but to pave the way for a solution that is truly transformative to your organization’s operations and strategy. For further details on enhancing capabilities, look to resources like our guide on digital twin technology.

Moving forward, there are no limits to the improvements and integrations you can achieve with your digital twin. As applications continue to broaden, businesses will uncover even more opportunities for optimization, cost savings, and innovative problem-solving through these virtual replicas.

How Do Digital Twins Enhance Operations?

Digital twins are revolutionizing industries by enabling a depth of analysis and precision in operations that was previously unattainable. This transformation is not just incremental; it’s monumental, significantly impacting manufacturing, product design, urban planning, and infrastructure management.

Streamlining Manufacturing and Supply Chains

In manufacturing, digital twins are indispensable assets. They allow for virtual testing of production lines, identifying bottlenecks and simulating potential interventions without disrupting ongoing operations. Businesses employing robust digital twin models have reported reductions in downtime and maintenance costs, while also achieving superior product quality—without the guesswork.

In supply chain operations, real-time data from digital twins enhances logistics, inventory management, and demand forecasting. Consider this: implementing digital twins has led to decreased waste levels, optimized stock levels, and more efficient route planning, significantly contributing to leaner, more responsive supply chains.

-

Real-time visibility into supply chain logistics.

-

Data-driven inventory optimization.

-

Predictive maintenance reducing downtime and costs.

Revolutionizing Product Design and Testing

When it comes to product design, digital twins offer an unprecedented platform for innovation. Engineers and designers can put their prototypes through stress tests in a variety of simulated environments, gathering data to refine their designs with precision. In the competitive automotive industry, companies using digital twins to test vehicle dynamics and safety features have not only expedited their time-to-market but also significantly heightened the safety and performance of their vehicles.

Performance testing, too, benefits immensely from digital twins. These models can mimic real-world scenarios, allowing teams to gather valuable insights into product behavior under varied conditions. This preemptive knowledge ensures products are resilient and customer-ready, streamlining the path from concept to launch.

-

Accelerated product development cycles.

-

Enhanced safety and performance metrics.

-

Proactive identification of design flaws.

Powering Smart Urban Planning and Infrastructure

Urban development and infrastructure management stand at the forefront of digital twin application. Cities can become smarter and more sustainable by integrating these technologies to manage utilities, traffic systems, and public services. For instance, digital twins of entire cities provide insights that drive smarter resource allocation and disaster response strategies, undoubtedly saving costs and improving citizen experiences.

Infrastructure management with digital twins is primarily about predictive maintenance and longevity. By forecasting wear and tear on public assets like bridges and roadways, planners and engineers can anticipate repairs before problems occur. Moreover, optimized energy usage and reduced environmental footprints speak volumes of the sustainability benefits that digital twins bring to the urban sphere.

-

Informed disaster response and resource allocation strategies.

-

Predictive insights for public asset management.

-

Sustainability through optimized energy usage and reduced environmental impact.

In the dynamic realm of urban development, these virtual models are not just a tool but a necessity for the cities of tomorrow. They are pivotal in shaping sustainable, responsive, and efficient urban spaces.

Digital twins carry the baton of innovation forward, galvanizing industries to reimagine their operations. For those willing to invest in the architecture and integration of digital twins, the benefits are clear: heightened efficiency, market agility, and sustainability. It’s not just about keeping up with the trends; it’s about setting them. For an exploration of practical applications in the automotive industry, consider reading our piece on digital twins in the automotive sector.

The next stage will delve deeper into the future possibilities, outlining how digital twins can not only optimize existing processes but also create entirely new paradigms for businesses and cities alike.

Overcoming Digital Twin Adoption Hurdles

As digital twin technologies mature, they bring with them a new set of adoption challenges. Recognizing and strategically addressing these challenges is imperative for organizations aiming to benefit from digital twins. Let’s dive into practical insights for navigating data integration, cost management, and infrastructure considerations effectively.

Navigating Data Complexity with a Unified Approach

The rich insights offered by digital twins depend on seamless data integration from diverse sources. However, achieving this level of harmony across different data streams and systems is often easier said than done. To tackle this, organizations must deploy robust middleware solutions that act as translators between disparate systems. This ensures consistent data flow and quality, which are imperative for the digital twin to function as intended.

Interoperability is another concern that can make or break a digital twin project. This goes beyond just speaking the same data language; it involves creating a digital ecosystem where different applications, platforms, and architectures work in concert. To facilitate this, employing standards like the Industrial Interoperability Standard allows systems to communicate effectively, minimizing the risk of data silos.

Cost and Complexity: Striking the Right Balance

The sophistication of digital twins often leads to apprehensions about high costs and overwhelming complexity. Transparent and phased strategies are key to managing both. Instead of a full-blown implementation, consider a modular approach to digital twin development. Start small, prove the value, and incrementally scale the digital twin implementation as your confidence and competence grow.

Cost considerations should account for the total cost of ownership (TCO), including development, operation, and future scalability. The digital twin should be seen as a long-term investment in efficiency and innovation. In many cases, the cost-saving potential of predictive maintenance or the revenue boost from accelerated product development can offset initial expenditures.

Ensuring Infrastructure Readiness and Expertise

Without the right infrastructure, a digital twin is merely a concept. Critically, this isn’t just about technology—it’s also about the personnel who design, manage, and interpret digital twin data. Both need to be of a high standard to support the complex simulations and analyses that digital twins perform. Investment in cloud computing platforms can provide the necessary computational power and scalability, while professional development programs can build your in-house expertise.

Partnering with educational institutions to foster a new generation of engineers and data scientists with digital twin expertise is not just beneficial; it’s a smart strategic move. It bridges the talent gap and creates a sustainable source of skilled professionals who can drive your digital twin initiatives forward.

To wrap up, meeting the challenges of digital twin adoption calls for deliberate, informed actions. Focus on these three areas to lay a solid groundwork:

-

Implement middleware and standards for robust data integration and system interoperability.

-

Begin with scalable, modular implementations to manage costs while progressively deepening integration.

-

Invest in infrastructure and talent development to ensure your digital twin is both powerful and utilizable.

Up next, we will discuss the exciting frontiers that digital twins are pushing across sectors and how your business can ride this wave to new heights of operational excellence. For insights on building a strong team to handle digital twin projects, consider staffing for digital transformation.

Final Thoughts

As we reflect on the journey of digital twin development, it’s clear that this technology is rapidly becoming integral to the way we approach complex systems across a multitude of industries. The development process, though intricate, provides a rich template for innovation—a canvas on which businesses can paint their strategies for improved operations and game-changing efficiencies.

Strategic planning and careful execution are paramount for successful adoption. Organizations seeking to make the most of digital twins must weigh their objectives against the nuances of data integration, infrastructure requirements, and the expertise needed to manage such sophisticated systems. It’s a multi-faceted endeavor that necessitates a forward-thinking and staged approach to investment and integration.

Looking ahead, the landscape for digital twins is one of substantial growth and unrelenting innovation. Early adopters stand to gain the most, positioning themselves at the vanguard of a technological movement that promises to redefine industry standards and operational excellence. We’re talking about a future where the line between physical and digital grows ever more indistinct, and where decision-making is consistently empowered by real-time data and simulations.

To thrive in this landscape, embracing digital twins is not just beneficial, it’s imperative. Here are considerations to keep in mind:

-

Strategic adoption fosters a competitive edge.

-

Comprehensive planning leads to effective execution.

-

Continuous innovation ensures future readiness.

Moreover, in a world where virtual experiences are gaining unprecedented momentum, the utility of digital twins will likely extend even further, intersecting with virtual and augmented reality to create immersive experiences across sectors.

At Newroom Connect, we recognize the transformative potential of digital environments such as virtual trade fairs, virtual showrooms, and e-learning platforms. In fact, the development and deployment of these virtual experiences serve as a testament to the power of digital replication and the boundless possibilities it holds. It isn’t just about technological prowess; it’s about building pathways that lead businesses to new efficiencies, enhanced learning experiences, and more engaging customer interactions.

In conclusion, digital twins are more than a technological advancement; they are the keystone of a new industrial paradigm—one that we at Newroom Connect are committed to advancing. We invite you to explore the potential and power of digital twins further with our innovative solutions. Step into this thrilling new arena with us, and let’s redefine reality together. For more information, connect with our team and see how digital twins can transform your business at Newroom Connect.