We at newroom connect know firsthand that the manufacturing landscape is evolving at an unprecedented rate. Digitial twins stand at the forefront of this transformation, offering a powerful toolkit for innovation and efficiency.

By mirroring physical assets with virtual replicas, manufacturers gain insights that drive better decision-making. This ability is reshaping everything from design processes to maintenance schedules, marking a significant leap in how industries operate.

Harnessing Digital Twins for Smart Manufacturing

The integration of digital twins in manufacturing isn’t just an improvement; it’s a ground-breaking shift that redefines production. A digital twin is essentially a dynamic digital representation of a physical entity or system. This concept hinges on the real-time collection, analysis, and application of data from the physical world to its virtual counterpart. Here’s how it revolutionizes the sector:

Digital twins go beyond mere 3D models. They encompass a wealth of data spanning the entire lifecycle of a product, from initial concept to decommissioning. Engaging with digital twin technology enables manufacturers to conduct simulations, troubleshoot issues, and optimize systems—before physical execution. The benefits of deploying digital twins are substantial:

-

Streamlined design phases with the ability to fine-tune products virtually leads to reduced time to market.

-

Enhanced performance analysis and predictive maintenance strategies reduce costly downtimes.

-

Real-time monitoring ensures continuous improvements and adaptations to production processes.

In smart manufacturing, digital twins are the engines powering intelligent factories. They seamlessly fit into the smart manufacturing milieu by connecting systems and promoting autonomous decision-making. Paired with IoT devices, digital twins collect data that fuels machine learning algorithms, empowering machines to predict failures and autonomously optimize operations.

Here’s what embracing digital twins in smart manufacturing looks like in practice:

-

Virtual testing of manufacturing processes minimizes errors and empowers agile responses to market demands.

-

Precise control over quality management thanks to real-time data and virtual scenario testing.

-

Creation of a safer work environment by simulating and mitigating potential hazards before they happen.

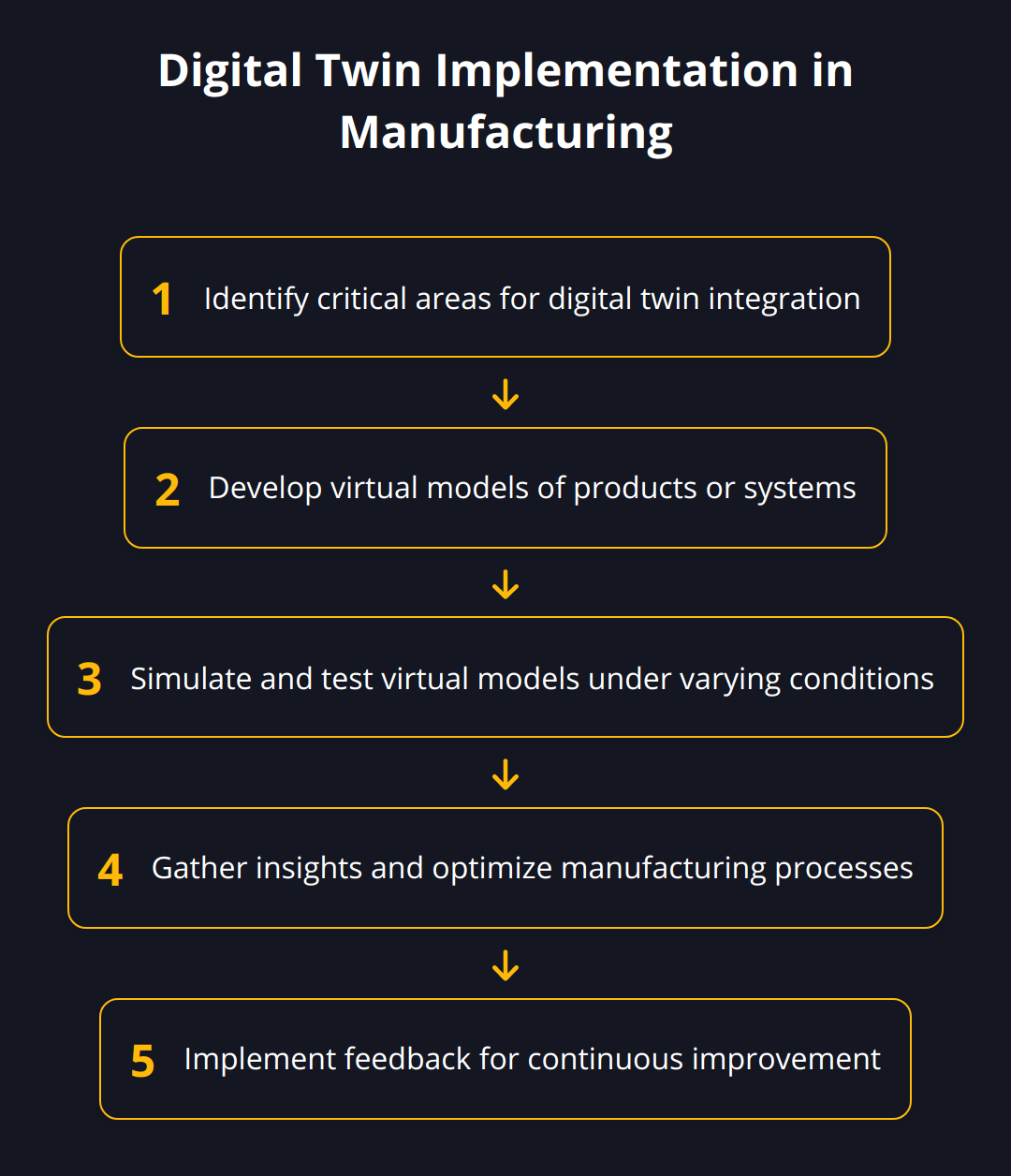

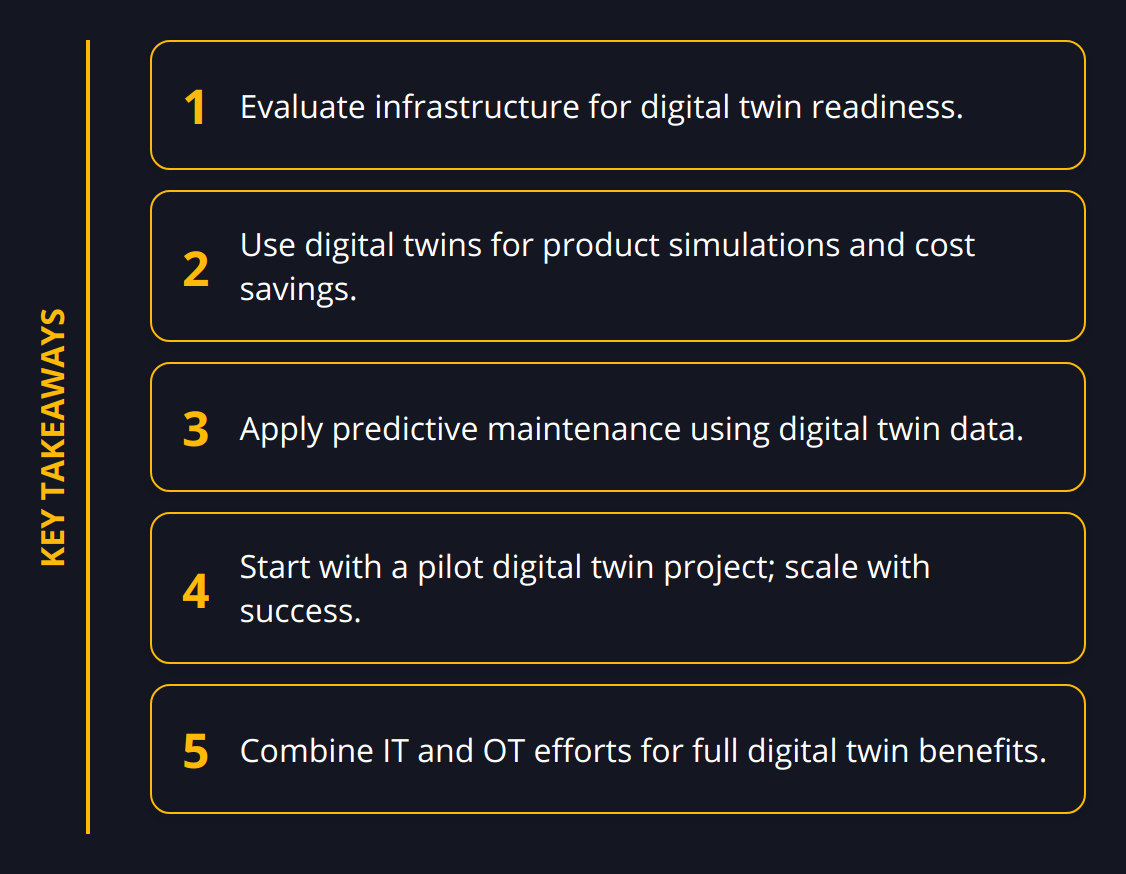

Consider these actionable steps to leverage digital twins in your manufacturing processes:

-

Evaluate your existing infrastructure for digital twin compatibility.

-

Use digital twins for complex product simulations, saving costs on physical prototyping.

-

Integrate digital twin insights to improve product lifespan and aftermarket services.

Digital twins aren’t a distant future technology—they’re here, and the manufacturing sector is already reaping the rewards. Industry leaders have witnessed a decrease in prototyping costs by effectively employing digital twins, with some even reporting a reduction in development times by up to 50%. Furthermore, products designed with digital twins in mind have shown a significant decrease in quality issues upon entering the production phase.

In conclusion, digital twins represent a transformative technology that smart manufacturing cannot afford to overlook. They serve as a keystone for innovative practices, bridging the gap between virtual planning and real-world execution. The data speaks: companies leveraging digital twins are setting new efficiency benchmarks and staying ahead in the competitive manufacturing domain. The age of intelligent manufacturing, powered by digital twins, is now.

How Do Digital Twins Elevate Manufacturing?

Digital twins revolutionize manufacturing by offering an unparalleled window into every aspect of the product development cycle, from nuanced design improvements to operational efficiency and strategic supply chain management. It’s a bold statement but backed by compelling evidence, digital twins present manufacturers with the opportunity to transform their processes for groundbreaking results.

Maximizing Efficiency in Design and Prototyping

By twinning the physical with the virtual, manufacturers are empowered to iterate designs rapidly and precisely. Virtual prototypes can undergo extensive testing without the cost and time of building a physical version. Engineers can modify and test multiple configurations in quick succession, slashing weeks or even months off development schedules. Data suggests that incorporating digital twins for design and prototyping can cut the number of physical prototypes needed, directly translating to material cost savings and reduced development cycles.

Optimized design flows further improve product quality. Digital twins provide deep insights into how design tweaks may perform in real-world conditions, long before any capital gets invested in a physical prototype. They successfully transition concepts to market-ready products with higher confidence levels and fewer redesigns, supported by the fact that 25% of products created with digital twins encounter fewer quality issues than those that aren’t.

Achieving Peak Operational Performance

Operational efficiency isn’t just about keeping machines running; it’s about preempting disturbances before they occur. Digital twins enable a paradigm shift in maintenance—from reactive to predictive. Real-time data harvested from IoT devices feeds into the digital twin, allowing for predictive analysis that can spot issues before they result in downtime. This isn’t speculative: companies that embrace predictive maintenance strategies are reporting decreased downtime and associated costs.

A prime example is the utilization of digital twins for equipment failure predictions, shaving off substantial amounts from maintenance budgets. These sophisticated models diagnose equipment conditions, leveraging historical and real-time data to forecast potential breakdowns and recommend suitable interventions. For instance, a predictive maintenance approach can diminish maintenance costs by 10 to 40%, according to industry analyses.

Streamlining Supply Chain Dynamics

Digital twins stand to make one of the most significant impacts within supply chain optimization. They create dynamic models that mirror real-time inventory levels, supplier interactions, and logistics operations. With comprehensive virtual modeling, manufacturers can plan more effectively for demand changes, inventory shortages, and even unexpected global disruptions, a specific requirement in today’s fast-paced market where supply chain hiccups can trigger significant losses.

Implementing digital twin technology builds resilience in supply chains, allowing for quicker adaptations to market fluctuations and a more enlightened approach to inventory management. As we refine supply chain digital twins, manufacturers note an improvment in inventory turns by up to 40%, confirming how transformative this technology is for managing complex global networks.

Manufacturers keen on capitalizing on these advantages should consider the following strategies:

-

Invest in powerful data analytics tools to seamlessly integrate with your digital twin.

-

Start small with a pilot digital twin project, then scale based on success and learning.

-

Prioritize collaboration between IT and OT departments to fully realize the benefits of digital twins.

-

Partner with digital twin experts from platforms like newroom-connect to fast-track your digital twin journey.

The data is inarguable: digital twins infuse manufacturing operations with unprecedented intelligence. Top sectors echo this sentiment, adopting digital twins as the core around which factories of the future are being built. As the embodiment of Industry 4.0, digital twins are not just another tool in the toolkit—they’re the synthesis of data and intelligence that is setting new horizons for manufacturers worldwide.

Digital Twins in Action

The wave of digital twins is revolutionizing various sectors, providing tangible benefits and optimized outcomes. Let’s look at concrete examples where digital twins have truly transformed manufacturing processes.

Ushering in Innovation in the Automotive Industry

In the automotive sector, digital twins accelerate the design and testing of vehicles. Manufacturers can now virtualize the entire vehicle development process, enabling rapid prototyping and testing of new car models. BMW, for example, uses digital twins to simulate vehicle dynamics and crash behaviors before building a single physical prototype, resulting in substantial cost savings and shorter development cycles. Incorporating digital twins in automotive manufacturing proves essential for keeping pace with the rapid changes in vehicle technology, especially with the shift towards electric vehicles and autonomous driving.

Soaring High with Digital Twins in Aerospace

The aerospace industry relies on precision and safety, where digital twins serve as an integral tool for performance optimization. Airbus has been a pioneer in employing digital twins to virtually test aircraft performance under various conditions. Through the virtual analyses, they are able to optimize flight operations and maintenance schedules, enhancing aircraft reliability and extending the lifecycle of their fleet. As these virtual platforms continue to improve, they will become indispensable in mitigating risks and ensuring optimal performance of aerospace vehicles.

Streamlining Electronics Manufacturing

Electronics manufacturers face the challenge of rapidly evolving technologies and the need for agile response to market demands. Digital twins assist in this arena by offering process automation and virtual testing of electronic components and systems. Companies like Intel have embraced digital twins to monitor manufacturing processes and predict outcomes with high accuracy. This has enabled better quality control and faster response times, leading to leaner production lines and improved product outputs.

Practical tips from these success stories include:

-

Implement digital twins early in the design process to save both time and resources.

-

Use virtual environments to test different scenarios and optimize product performance.

-

Integrate predictive maintenance into your digital twin strategy to anticipate and prevent potential downtimes.

These examples are not standalone cases but a representation of a broader trend. The effectiveness of digital twins is evident by the numbers: over a third of companies in these advanced sectors are citing improved operational efficiency, demonstrating the competitive edge that digital twins provide. Whether it’s automotive, aerospace, or electronics, the use of digital twins is synonymous with innovation and ongoing improvement.

No matter the industry, digital twins represent the next evolutionary step in manufacturing. They offer more than just a competitive advantage; they are redefining the very essence of product development and market delivery. Now is the time to harness the transformative potential of digital twins and gain the insights to outperform in the manufacturing landscape.

Digital twin implementation strategies can vary greatly, but these real-world examples provide a foundational understanding that can be adapted and applied to other sectors seeking to leverage this technology. Manufacturers eager to explore how digital twins can benefit their production lines should take heed of these case studies and consider similar approaches to foster innovation and efficiency in their processes.

Wrapping Up

The transformative impact of digital twins on manufacturing is clear and substantial. They reinvent product design, optimize operations, and reshape supply chains, making manufacturing more agile, innovative, and efficient. The use of digital twins signifies more than progress – it heralds a new era where the integration of virtual and physical worlds drives unparalleled outcomes.

Adapting to this digital revolution is essential. It requires an investment in technology and a willingness to embrace new methodologies. As manufacturing evolves, so too must the mindset of industry leaders and the strategic vision of companies. The future is bright for those who capitalize on the opportunities presented by digital twins. The potential for achieving optimal efficiency, reduced costs, and enhanced productivity is immense, paving the way for a smarter, more sustainable manufacturing landscape.

Factoring in the digital twin advantage, future manufacturing will be characterized by:

-

Rapid prototyping and development

-

Predictive maintenance for minimizing downtime

-

Supply chain resilience

Manufacturers are encouraged to foster an environment that facilitates digital twin integration. Embracing this technology is no longer optional for those seeking to maintain a competitive edge. The benefits, already evidenced in the enhanced performance of early adopters, underscore the role of digital twins as a cornerstone for innovation.

At newroom connect, we understand the power and significance of digital technologies in revolutionizing industries. We assist businesses in creating captivating virtual experiences that can showcase products, offer e-learning opportunities, and much more. With our cutting-edge platform, your company can embark on the digital twin journey, positioning your brand at the forefront of the industry. Explore our offerings and let us help you achieve a successful transition into the digital future.

In conclusion, the manufacturing industry stands at a pivotal moment where the adoption of digital twins is not just beneficial, but imperative for success. As the landscape becomes increasingly complex and competitive, the acceleration and efficiency afforded by digital twins make them indispensable. It is a pivotal time for manufacturers to embrace digital transformation with an eye on sustainability, cost-effectiveness, and innovation—the hallmarks of next-generation manufacturing.